How was the 3D model created?

For industrial area common practice is to make an EPCI tender. Where E – means Engineering, which includes FEED study.

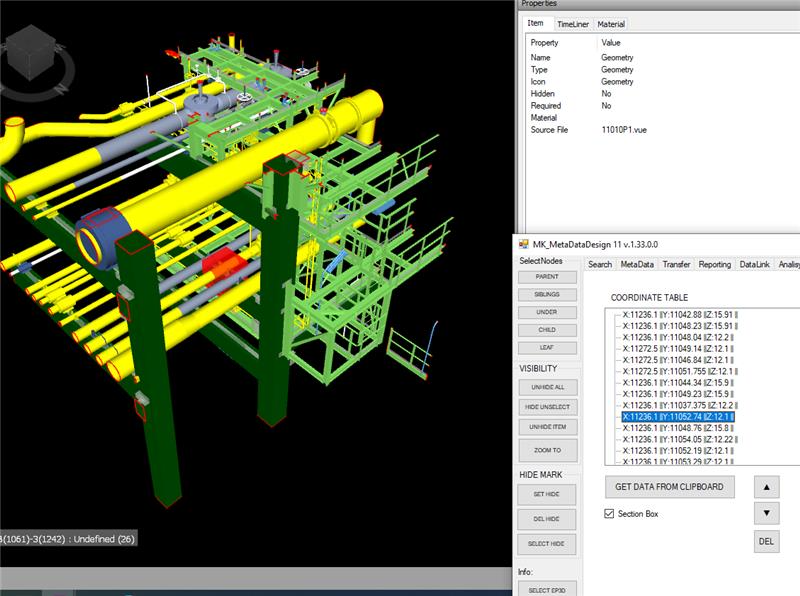

Rough 3D model appears at FEED study to help briefly estimate expenses, clarify technical details, define approximate facility layout.

When Final Investment Decision is made – Engineering start to model facility with all details.

Basically, 3D model is a product of engineering processes, as well as drawings, take off quantities, and specifications.

Who uses 3D model in Construction?

Engineers – use 3d model to create a detailed drawing, estimate quantities,

prevent clashes btw disciplines (pipe vs concrete wall vs HVAC, etc).

In last decade it became also more common to see at construction site due to fact of improvement of 3D model quality and liberation of 3D tools for model review

(IFC standard, NavisWorks Freedom, Web Based online viewers)

It’s faster to check 3D model at site, rather than make a clarification request to Engineering

If in case of drawings issues – some labels might be missed, some sections might do not have detail dimension.

For some models 2d slices might be hard to read as is, but these all start to make sense when you see 3D.

What is the input for 3D model?

Engineering take input from Client requirements and Technology schema developed for project.

Based on this data engineers estimate, calculate, and make model with respect to safety, constructability, local regulations, and extreme physical challenges:

- Significant snow load and extreme low temperatures in Arctic

- Extreme high temperatures in Middle East

- Risk of explosions and fire for Petrochemical facilities

- Extreeme pressure for sub see projects

- Criogenic temperatures for LNG projects

And of course – tight timeframe schedule it always challenge by it self. Reducing time from construction start to finish – create massive impact on project revenue.

What are the the major advantages of the 3d Model

In general 3D model increase cost of engineering due to high cost of licenses and manhours required for modeling processes.

Result – more accurate detailed information for constructions, with impressively less mistake rates.

- 3D model allows to spot clashes btw disciplines, subcontractor before it reach construction process. Each mistake at Construction stage cost a lot of money and cause delays.

- Give same point of view for Engineers, Managers, Client specialists:

- accurate 3D model easier manage due technical review, rather than infinite stack of Drawings and Tables.

- Its better to see 3D rather than comparing dimensions btw barely related drawings.

- This accuracy allow to make more dense structures, due to fact that each dimension is reliable, before it was common to modify dimensions at site.

- This reliability of element dimensions allow to scatter work load among fabricators, instead of receiving raw materials at site, project can rely on prefab elements. This reduce cost and time, give a maneuver to scale up productivity by involve several fabrication facilities among the globe

- As result we get more detailed and reliable documentation for Procurement and Construction processes. Which also improve maintenance at execution stage of facility.

Is this a process that is new at Construction site?

3D modeling process for Facility engineering – used for decades, start with Oil And Gas fields, and became mandatory for basically every industial facility.

Now a days 3D model became point of interest for all parties (EPCI Contractor, Client, Subcontractors).

Key difference is cloud based tools became available in recent years, which give reliable ground for colaborative activites.

With online tracking systems each element might be tracked from drawings to fabrication, painting, shipping, erection.

With cloud based data analisys solutions such as PowerBI – we can get insights out of this data.

With liberated 3D model all this data became Reliable tools for analyze and manage construction data in terms of fabrication, erections, commissioning readiness.

What are the points to be mindful with the 3D model

Common mistake among 3d evangelist – is that 3D model shall remove drawings from process at some point.

In reality – drawing detail based on 3D model is a key factor to ensure 3D model validity for project requirements,

fabrication standards and quality demands.

Hight quality of 3D is not achievable without detailed 2D drawings and vice versa.

For construction site – 3D model is useful tool to resolve question if 2D details is not clear.

Now with Digitalization progress in terms of Construction Progress tracking, with new cloud-based

Data Analysis tools, and Web based Model review – company able to utilize 3D for:

- Constructability study,

- define short and mid terms Priorities,

- check Subcontractor progress and progress data,

- Identify impact of incidents at module and area based due to Material shortage, Damage, Erection stage of different disciplines.

- Another important task is to Calculate current available Workfront.

Engineering model give Total Workfront, construction operate with a plan for coming 1-2-3 months and only partial concreate scope.

It’s important to hire right number of employees to do the job at site based on

fabrication progress, stock availability, construction progress.

If one of Piperack column is in delay due to transportation damage, or casting mistake,

even if we had pipes available at site layout, we cannot consider it as Workfront for the moment.

Such details is about to resolve by Construction Management team, and 3D became essential tool for:

– communication,

– progress analysis

– subcontractor progress review

– data consistency check

– short term planning based on Data

3D model is essential to Data Driven Construction methodology implementing at site. Which is key requiremet for facilitation of AI tools at Construction Landscape.